TESTING EQUIPMENT FOR NON-DESTRUCTIVE TESTING (NDT)

We offer state-of-the-art testing equipment for non-destructive testing for a wide range of industrial applications. Our testing machines are individually designed and constructed according to your requirements.

Deprecated: strtolower(): Passing null to parameter #1 ($string) of type string is deprecated in /www/laubingerrickmann_595/public/wp-content/plugins/elementor/includes/utils.php on line 727

ULTRASONIC TESTING EQUIPMENT

NON-DESTRUCTIVE QUALITY TESTING

ULTRASONIC TESTING EQUIPMENT

We offer state-of-the-art testing equipment for non-destructive testing for a wide range of industrial applications. This could be both standard equipment and testing machines designed and constructed according to your individual requirements.

lorem ipsum

Aerospace

The components used in aviation and aerospace are subject to very strict quality controls. For the inspection of these components, a wide variety of linear mechanics as well as robotic systems are used. Many well-known aircraft manufacturers and their suppliers rely therefore on L+R inspection mechanics for non-destructive testing (NDT).

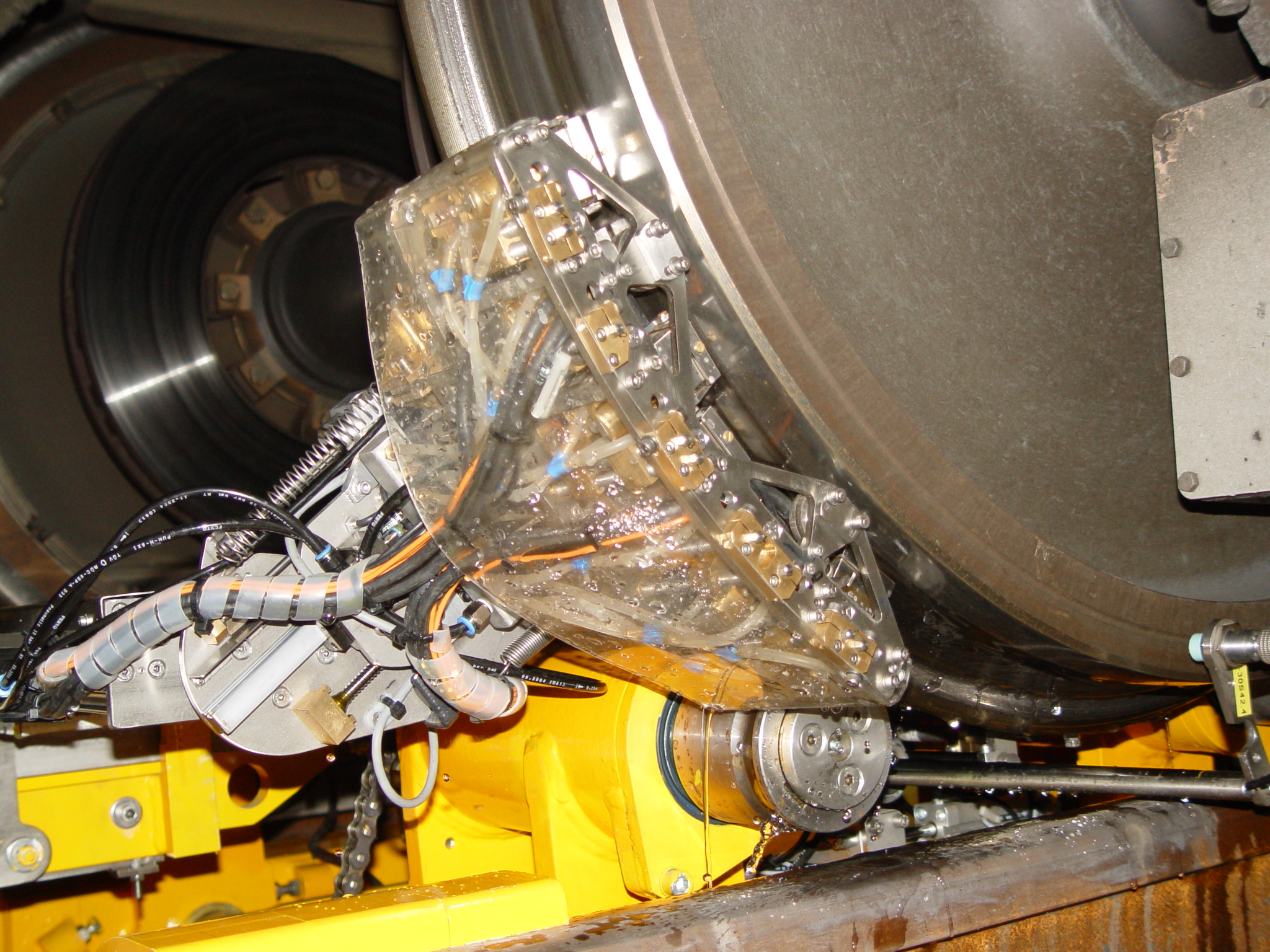

Transportation industry (railway)

One sector of the transportation industry in which L+R's innovative systems are in great demand is the railway industry. In the recent past, a wide variety of different mechanical tests have been realized. Among those are e.g. systems for testing wheelsets while installed, or stationary wheelset testing systems. We have also developed concepts for testing solid and hollow shafts.

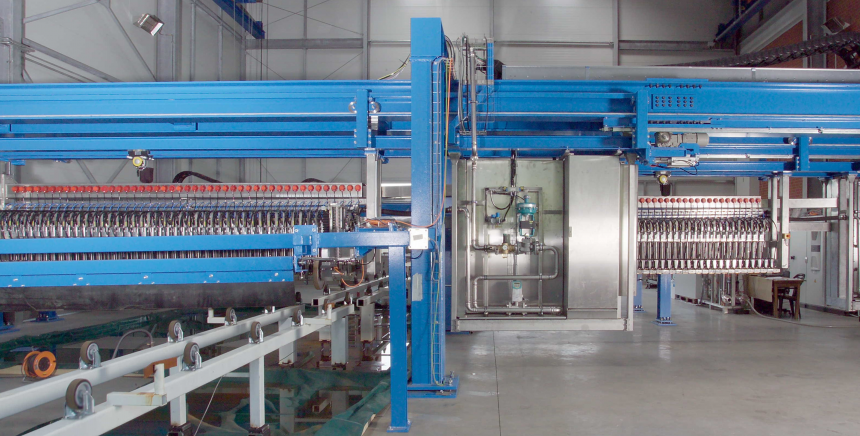

Steel and aluminum industry

In recent years, the quality requirements for heavy plate and its downstream products have increased steadily. Ultrasonic testing systems in rolling mills enable the producer to test the plates in-line (fully automated) according to different standards and to document the measurement results accordingly. Steel producers worldwide rely here on the proven mechanical testing for sheet and plate from L+R.

Based on many years of worldwide experience, our product range offers the optimum solution for each customer, it could be the retrofitting of sheet metal testing into existing production lines as well as completely new designs.

Aerospace

The components used in aviation and aerospace are subject to very strict quality controls. For the inspection of these components, a wide variety of linear mechanics as well as robotic systems are used. Many well-known aircraft manufacturers and their suppliers rely therefore on L+R inspection mechanics for non-destructive testing (NDT).

NON-DESTRUCTIVE QUALITY TESTING

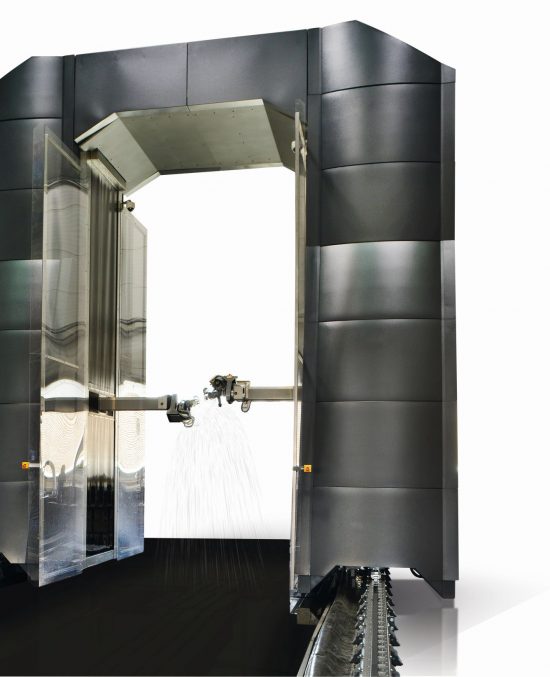

RÖNTGENANLAGEN

Auch die zerstörungsfreie Prüfung von Rohren und Knüppeln gehört zum Leistungsspektrum der Laubinger + Rickmann GmbH & Co. KG. Hier werden Systeme für Röntgen-, Ultraschall-, Wirbelstromprüfungen sowie fluoreszierende Farbeindringprüfung kundenspezifisch geplant und realisiert.

Die Anwendungsmöglichkeiten gehen von der Rohrendenprüfung über die Schweißnahtprüfung von Längs- oder Spiralnaht geschweißten Rohren bis hin zur Vollkörperprüfung.

lorem ipsum

lorem ipsum

Zur Qualitätskontrolle vieler Rohrtypen - insbesondere in sicherheitsrelevanten Bereichen, wie bei Pipelines usw. - sind Qualitätszertifikate notwendig, welche mit Hilfe von Prüfmechaniken von L+R erstellt werden. Für die Bereitstellung der Röntgen- und Auswertetechnik sorgen unsere branchenbekannten Partner.

lorem ipsum lorem ipsum lorem ipsum lorem

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

Transportation industry (railway)

One sector of the transportation industry in which L+R’s innovative systems are in great demand is the railway industry. In the recent past, a wide variety of different mechanical tests have been realized. Among those are e.g. systems for testing wheelsets while installed, or stationary wheelset testing systems. We have also developed concepts for testing solid and hollow shafts.

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

Steel and aluminum industry

In recent years, the quality requirements for heavy plate and its downstream products have increased steadily. Ultrasonic testing systems in rolling mills enable the producer to test the plates in-line (fully automated) according to different standards and to document the measurement results accordingly.

Steel producers worldwide rely here on the proven mechanical testing for sheet and plate from L+R.

Based on many years of worldwide experience, our product range offers the optimum solution for each customer, it could be the retrofitting of sheet metal testing into existing production lines as well as completely new designs.

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

NON-DESTRUCTIVE QUALITY TESTING

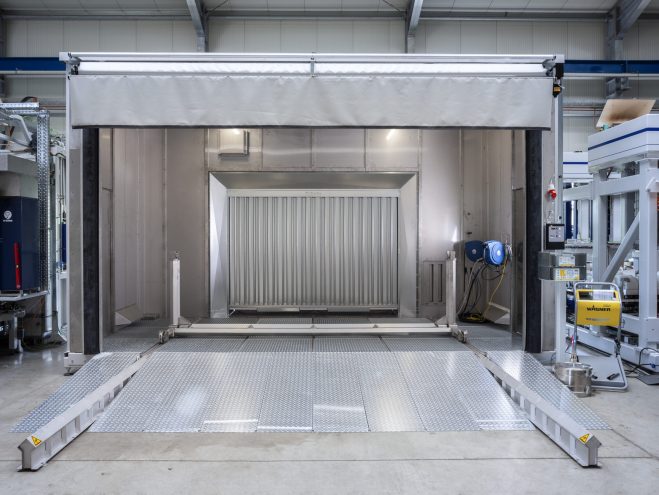

CRACK TESTING EQUIPMENT

The crack detection systems or dye/liquid penetration systems from L+R are used for – mostly fluorescent – penetrant testing (PT). They represent an essential part of quality control for aluminum castings and forgings, especially for safety-critical components. These systems are following the requirements of the respective testing process and of the tested parts. Our area of expertise are customer-specific solutions with regards to throughput, degree of automation and space restrictions, i.e. L+R offers optimal solutions for individual needs. In order to guarantee an optimum inspection process for each customer, L+R cooperates with well-known partners in the industry. In close cooperation with the customer, the test equipment manufacturers and independent consultants, the individual process is designed with efficiency, reliability, ergonomics and economy in mind.

lorem ipsum

Crack testing by means of the dye/liquid penetrant test method (PT/DPT/LPT)

- Pre-cleaning with subsequent drying (optional)

- penetration

- multi-stage intermediate cleaning

- wetting with developer (optional)

- drying

- testing

- Post-cleaning (optional)

Manual and automatic

L+R offers its customers a loading and unloading concept tailored to the respective application, from manual loading to fully automatic loading by a robot and integrating the loading into fully automated production lines. Parts can be transported through the system either manually or automatically by means of a conveyor system. L+R generally uses 'power and free' overhead conveyors, accumulating conveyors, and roller table systems.

Sustainable and efficient

In order to meet the growing demand for plant efficiency and reduction of operating costs, L+R is looking for improvements to implement at each single step of the process. For example, through advanced thermodynamic processes L+R has reduced the power consumption of the drying system by about 75%. The secret for our success and our innovative strength lies in the close cooperation with our customers, partners as well as research institutes.

Crack Testing Equipment (PT)

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

NON-DESTRUCTIVE QUALITY TESTING

ZERSTÖRENDE PRÜFANLANGEN

Für Sonderprüfungen bietet L+R maßangefertigte Lösungen

lorem ipsum

lorem ipsum

Zur Qualitätskontrolle vieler Rohrtypen - insbesondere in sicherheitsrelevanten Bereichen, wie bei Pipelines usw. - sind Qualitätszertifikate notwendig, welche mit Hilfe von Prüfmechaniken von L+R erstellt werden. Für die Bereitstellung der Röntgen- und Auswertetechnik sorgen unsere branchenbekannten Partner.

lorem ipsum lorem ipsum lorem ipsum lorem

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

lorem ipsum lorem ipsum lorem ipsum lorem ipsum lorem ipsum

Customer-oriented solutions from a single source

Do you have any questions about our products?

Then please feel free to contact us.